Introduction to Precast Wheel Stops

When it comes to ensuring safety in parking lots and driveways, precast wheel stops play an essential role. These durable barriers help to prevent vehicles from going beyond designated parking areas. In this comprehensive guide, we will explore the benefits, installation process, and maintenance of precast wheel stops.

Benefits of Using Precast Wheel Stops

Precast wheel stops offer a multitude of advantages, making them a popular choice for many applications:

- Durability: Made from concrete, these wheel stops can withstand heavy vehicles and harsh weather conditions.

- Cost-Effective: Precast wheel stops are generally more affordable compared to other materials like plastic or rubber.

- Ease of Installation: They are relatively simple to install, reducing labor costs and time.

- Environmentally Friendly: Concrete wheel stops can be made from recyclable materials, reducing their environmental impact.

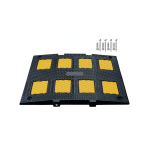

Types of Precast Wheel Stops

There are various types of precast wheel stops available on the market, each designed to meet specific needs:

Standard Precast Wheel Stops

These are the most common type, ideal for most parking lots and residential areas. They are typically made from concrete and can be painted in various colors to enhance visibility.

Heavy-Duty Precast Wheel Stops

Designed for industrial applications, heavy-duty wheel stops can endure more significant impact and wear. They are perfect for areas with heavy truck traffic.

Installation Process

Proper installation is crucial to maximize the effectiveness of precast wheel stops. Here is a step-by-step guide:

- Site Preparation: Clear the area of debris and ensure it is level.

- Marking: Use chalk or marking paint to outline where each wheel stop will be placed.

- Drilling: Drill holes into the ground at the marked locations. The holes should match the pre-drilled holes in the wheel stops.

- Anchoring: Secure the wheel stops using concrete anchors or rebar pins.

- Final Check: Ensure that each wheel stop is securely anchored and aligned correctly.

Maintenance Tips

To keep your precast wheel stops in optimal condition, follow these maintenance tips:

- Regular Inspections: Check for any damage or wear and tear at least once a month.

- Cleaning: Remove any dirt or debris that may accumulate around the wheel stops.

- Repainting: Reapply paint as needed to maintain the visibility of the wheel stops.

- Repairs: Address any cracks or chips immediately to prevent further damage.

Conclusion

Precast wheel stops are a practical and effective solution for controlling vehicle parking and ensuring safety. Their durability, cost-efficiency, and ease of maintenance make them an excellent choice for various settings. For more details on precast wheel stops or to inquire about prices, visit Unimat Traffic.

Get More Information

If you’re interested in learning more or getting a quote for precast wheel stops, we encourage you to visit our website. Our team is ready to assist you with all your needs!